Scenario 1: Your company designs and manufactures solar racking equipment. Your current system utilizes an extruded bracket which costs $3.50 per solar panel. You have designed a new sheet metal bracket to save cost, and you've received quotes form three different suppliers.

| Option | Old Time Supplier | Speedy Sheet Metal, Inc | Stamp-ede Industries | ABC Stamping |

| Fabrication Method | Extrusion | Lasercut + Form | Laser Blank + Stamp | Progressive Stamping |

| Tooling Cost | None | $1,500 | $25,000 | $38,000 |

| Piece Price | $3.50 | $5.10 | $2.45 | $1.95 |

\1. What is the total cost to order 10,000 parts from each supplier? Your cost should include the one-time tooling cost as well as the price per part.

Old Time Supplier = \(0 + 10000\times3.50 = 35,000\)

Speedy Sheet Metal, Inc = \(1500 + 10000\times5.10 = 52,500\)

Stamp-ede Industries = \(25000 + 10000\times2.45 = 49,500\)

ABC Stamping = \(38000 + 10000\times1.95 = 57,500\)

\2. What is the total cost to order 250,000 parts from each supplier?

Old Time Supplier = \(0 + 250000\times3.50 = 8,750,000\)

Speedy Sheet Metal, Inc = \(1500 + 250000\times5.10 = 1,276,500\)

Stamp-ede Industries = \(25000 + 250000\times2.45 = 637,500\)

ABC Stamping = \(38000 + 250000\times1.95 = 525,500\)

\3. What is the cheapest option for 250,000 parts?

ABC Stamping.

\4. How much money does this cheapest option save vs. the baseline (current) design?

\(8750000 - 525500 = 8,224,500\)

\5. Write an equation for the total cost ("TC") as a function of order quantity ("Q") from each supplier.

\(TC_{\text{Old Time Supplier}} = 0 + Q\times3.50\)

\(TC_{\text{Speedy Sheet Metal, Inc}} = 1500 + Q\times5.10\)

\(TC_{\text{Stamp-ede Industries}} = 25000 + Q\times2.45\)

\(TC_{\text{ABC Stamping}} = 38000 + Q\times1.95\)

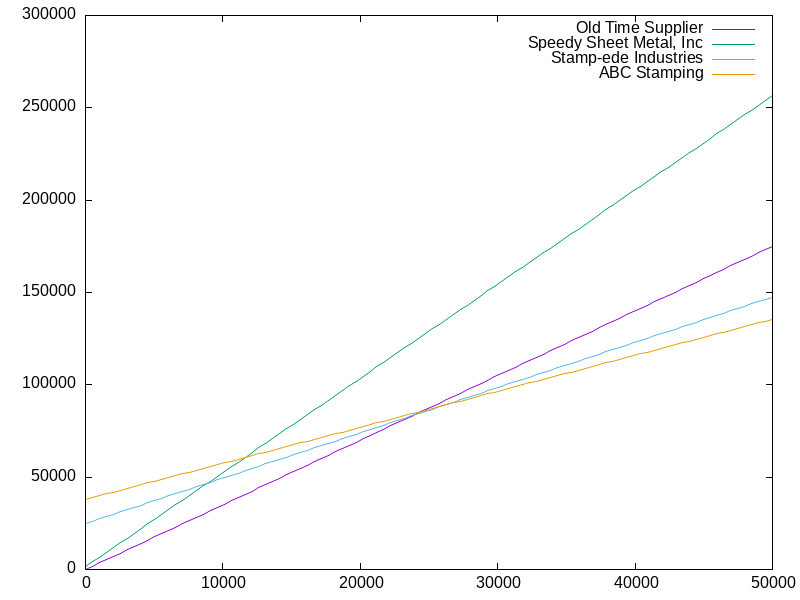

\6. Graph

\7. How does the most competitive supplier change based on total quantity?

For very small orders, the current supplier is the best due to the low startup cost. As the graph moves along, however, the cheaper parts available from Stamp-ede outpace the startup cost associated. Even further down the graph, the even cheaper parts made from ABC Stamping outpace Stamp-ede's output.

\8. Do some internet research to find out approximately how many solar panels were installed in the US in 2018. Assume your company supplies racking used to mount 5% of these. What supplier should you choose and why?

According to power-technology, 314,000 solar panels were installed in the US in 2018. If true, that means our company would be responsible for 15,700 solar panel installations. For this, the most cost-effective supplier would be the old supplier.

\9. List at least 5 factors besides total cost that might influence your choice of supplier.

Locality, efficacy of product, moral reasons, speed of manufacture, reaction to design changes, etc.